Features

The Geka ALFA Series is a precision-engineered CNC punching and shearing machine tailored for steel fabricators with demands for medium to high-output production. In this ALFA-500 version, fabricators can efficiently process flat bars ranging from 6 to 12 meters in length. This versatile machine also offers a wide range of optional features, including marking, drilling, mitre shearing, and automatic loading and unloading capabilities, enabling fabricators to elevate their production capabilities to new heights.

| ALFA SERIES | ALFA-150 | ALFA-500 | ALFA 500-165 | ALFA 500-220 | |

| Minimum flat bar (45kg/mm2) | mm | 25 x 4 | 50 x 5 | 50 x 5 | 50 x 5 |

| Maximum flat bar (45kg/mm2) | mm | 150 x 12 | 500 x 20 | 500 x 25 | 500 x 35 |

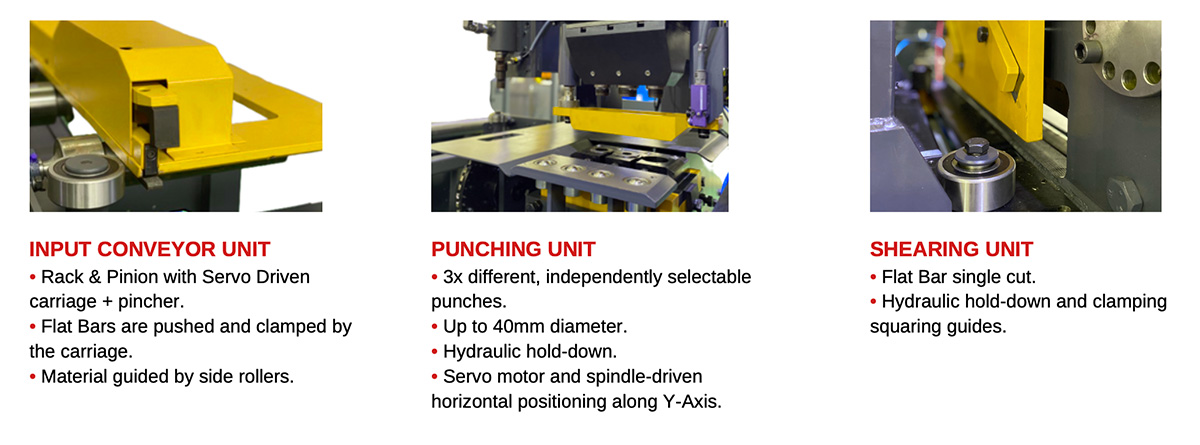

| Infeed system | - | Roller | Pincher | Pincher | Pincher |

| Maximum diameter | mm | 31 | 40 | 40 | 40 |

| Number of punches | no. | 2 | 3 | 3 | 3 |

| Center punch power | tons | 64 | 110 | 165 | 220 |

| Sides punch power | tons | - | 66 | 123 | 165 |

| Shear power | tons | 64 | 187 | 300 | 450 |

| Marking wheel | - | - | Available as optional | ||

| Automatic loading transfer | - | - | Available as optional for 6 & 12 meters | ||

| Automatic unloading transfer | - | - | Available as optional for 6 & 12 meters | ||

| Drilling unit | - | - | Available as optional, up to 40mm | ||

| Mitre shearing | - | - | Available as optional | ||

| Operating software in Windows 10 | Standard | LinePro Net | |||

| Optional | LANTEK | ||||