The partnership between Daito-Seiki Japan and Industrial Machinery Sales & Service represents a significant advancement in delivering cutting-edge structural steel processing solutions to industries in Australia and New Zealand.

Daito Seiki is a renowned manufacturer of precision industrial machinery, recognised for its cutting-edge technology and innovation. Specialising in CNC Drilling Machines, High-Speed Band Saws, and Robotic Plasma Coping Machines, for strudel steel processing. Daito Seiki ensures unmatched precision, reliability, and efficiency.

Their focus on advanced technology, especially with Combined Multi-Tasking Machines, optimises space and costs, empowering industries to boost productivity and adapt to evolving needs swiftly. This collaboration combines Daito Seiki’s engineering excellence with Industrial Machinery’s commitment to advanced solutions, leading to world-class industrial machinery in the steel processing sector across Australia and New Zealand.

About Daito-Seiki Japan

Main Products

MARKET LEADERS

CNC Drilling Machines

Band Saw Machines

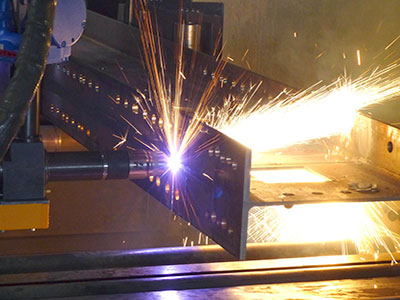

Plasma Coping Robots

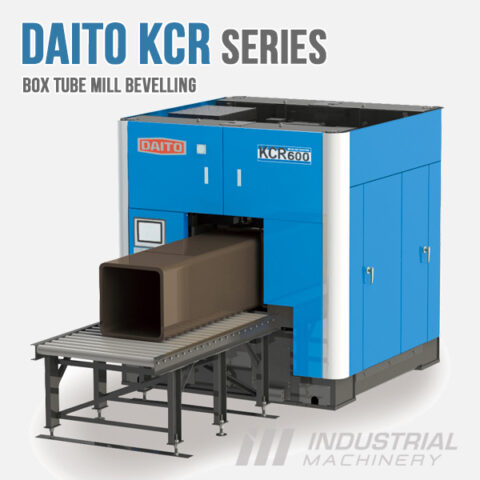

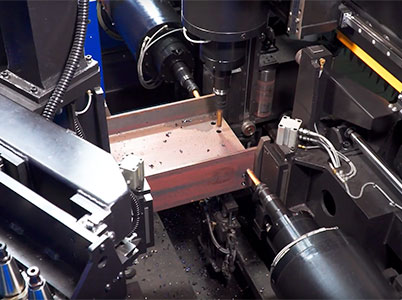

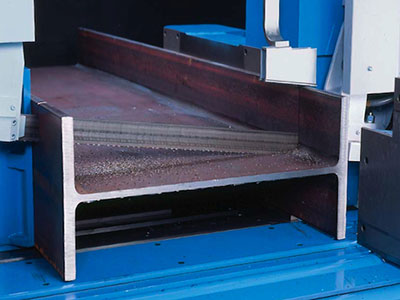

Mill Bevel Machines

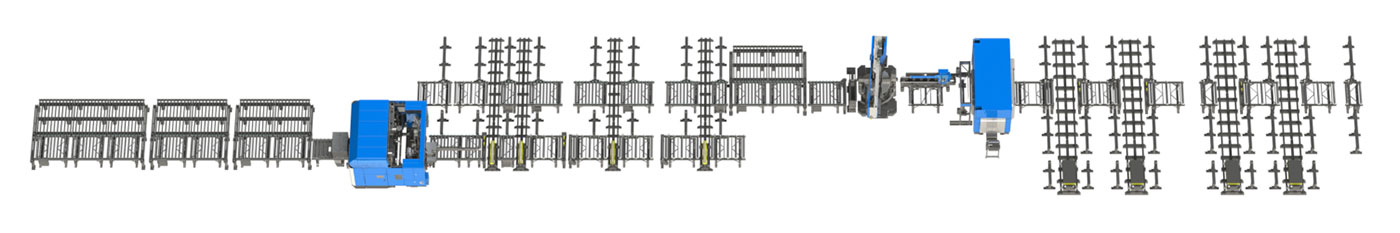

Fully Customisable Beam Lines

With Daito’s groundbreaking unitised machines and the innovative beam line configuration, achieving your desired outcomes for configuration and layout has never been easier.

Advanced Features

Daito embraces the high standards of the Japanese machine tool industry, prioritizing advanced features aimed at optimizing efficiencies, ensuring reliability, and enhancing overall functionality.

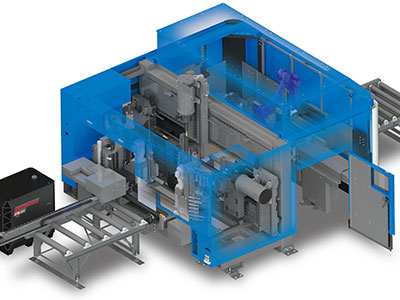

Combined Machines

WORKSHOP SPACE SAVER

Daito leads the way in combined Multi-Tasking CNC machine tools for structural steel processing. By integrating multiple machines within a single footprint, Daito significantly reduces the workshop space required and minimizes investment costs. This innovative approach allows for the production of the same parts at a lower cost per piece, ensuring both efficiency and cost-effectiveness

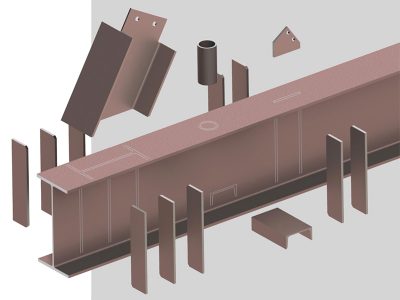

Layout Marking

TIME SAVER

Daito machines equipped with drilling units are exceptional in producing fast, clean, and accurate weld layout lines and letters on all four sides of the workpiece. This not only saves precious time and resources but also notably reduces the occurrence of human errors during the marking process.

Advanced Material Handling

LABOUR SAVER

In the area of material handling solutions, Daito takes a distinct approach. Our labor-saving loading and unloading systems are engineered not only to save time and manpower but also to accommodate a wide range of profiles in terms of size and weight. Moreover, our systems are designed to offer flexibility, catering to various budgets.

Robot Technology

THE FUTRE IS NOW

The future is now with Daito, the current world leader in robot plasma cutting machines showcased through their CR Series CNC Coping Robot Line and the highly sought-after DCM series, combining drilling, coping, and marking functions.

Daito now sets its sights on introducing cutting-edge robotic welding lines to fabrication workshops worldwide. Given their Japanese origins, their advancement in this technology is anticipated to establish them as market leaders. Stay tuned for more information coming soon.