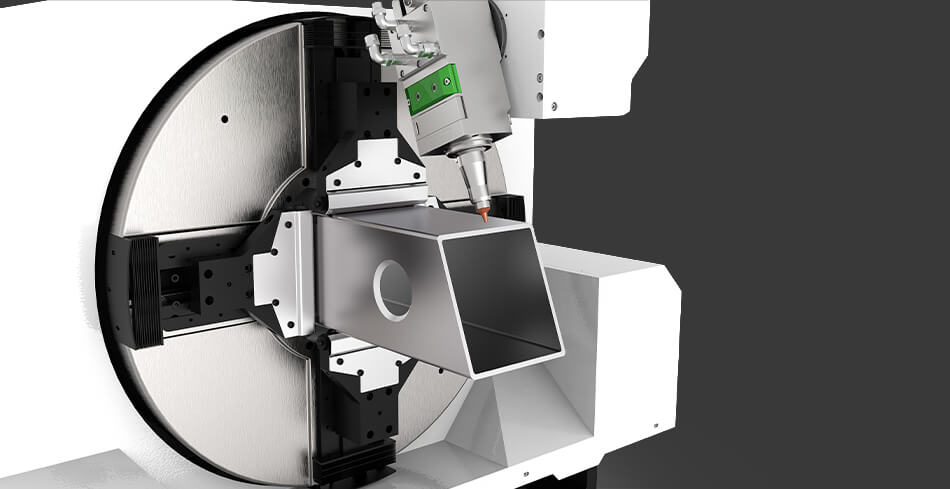

Tube laser cutting machines have a wide range of applications across various industries due to their versatility, precision and efficiency. Here are some of the common industries that benefit from the use of tube laser cutters:

Application industry of tube laser cutter:

Automotive manufacturing industry:

It has a high demand for efficiently produced parts. To meet the fast-paced nature of car manufacturing, precise and consistent parts are required, with minimal variation between each piece, while maintaining high production rates. Laser cutting is an excellent solution that offers speed, precision, and consistency simultaneously. Examples of components commonly produced using laser cutting include sheet metal body elements and seat fabrics.

Medical Equipment Industry:

In the medical equipment industry, complex diagnostic equipment like X-ray and FMRI machines require the integration of various manufacturing technologies. Laser cutting is a versatile method that can be utilized to produce several components for these machines, including sheet metal housings.

Construction Industry:

The construction industry is responsible for constructing various large-scale projects, including bridges, tunnels, residential buildings, and commercial structures. Laser cutting is commonly used in the production of structural steel for these projects. Connection plates and base plates, which are crucial components in steel construction, are efficiently manufactured using laser cutting due to its speed and precision. With major steel construction projects requiring thousands of these components, laser cutting offers a significant advantage. Additionally, tube laser cutting is extensively utilized for fabricating structural elements in the construction industry.

Agricultural Industry:

The agricultural industry plays a crucial role in large-scale cultivation of livestock and crops to meet the demands of food production. To efficiently produce high volumes of food, modern agriculture relies on heavy machinery and equipment such as planting machines, fertilizing machines, and bulk storage tanks. These machines often consist of complex, flat parts that are joined together using welding or fasteners. Laser cutting is an ideal method for economically producing these components due to its precision and efficiency. Additionally, tube laser cutting is extensively used in the agricultural industry for cutting holes and slots into square or round tubing, which is commonly utilized for structural elements in agricultural equipment.

Fitness equipment industry:

The tube laser cutter plays a crucial role in the manufacturing process. This advanced technology allows for precise and efficient cutting of various types of tubes used in the production of fitness equipment. From elliptical machines to weightlifting racks, tube laser cutting machines are utilized to create intricate and accurate cuts in the metal tubes that form the structure of these fitness machines. One of the primary advantages of using a laser tube cutter in the fitness equipment industry is its ability to cut complex shapes and patterns with high precision. This ensures that the tubes fit together seamlessly during assembly, resulting in sturdy and reliable fitness equipment. Additionally, the speed and efficiency of tube laser cutting machines allow for faster production times, enabling manufacturers to meet the demands of the market.

Cutting Material of Laser Pipe Cutting Machine :

Explore the materials that can be effectively cut using tube laser cutters. We will be focusing on common materials including stainless steel, carbon steel, iron, and aluminum. Understanding the properties of these materials and the best practices for cutting them are essential to achieving precise and efficient results.

Stainless Steel: Stainless steel is a popular material in various industries due to its durability and corrosion resistance. Tube laser cutting machines equipped with fiber lasers are ideal for cutting stainless steel. These machines provide high precision and speed, allowing for intricate designs and clean cuts. With minimal heat-affected zones, tube laser cutters ensure a high-quality finish, making them a go-to choice for stainless steel cutting applications.

Carbon Steel:

Carbon steel is also a widely used material, because of its strength and affordability. Laser tube cutters, especially those with high power fiber lasers, are highly effective in cutting carbon steel. These machines offer exceptional cutting speeds and precision, enabling manufacturers to achieve complex designs and smooth edges. The versatility of tube laser cutters makes them suitable for cutting thin to thick carbon steel sheets.

Iron: Iron usually used in manufacturing and construction industries. Laser tube cutting machines equipped with plasma cutting technology are the preferred choice for cutting iron. Plasma cutting machines generate a high-temperature plasma arc that swiftly melts and cuts through iron, resulting in precise and efficient results. This method is suitable for cutting thicker iron materials.

Aluminum: Aluminum is often used in industries such as aerospace and automotive due to its lightweight nature and corrosion resistance. Aluminum may be cut with tube laser cutting machines equipped with suitable optics. These machines effectively handle the high reflectivity of aluminum while ensuring minimal thermal distortion. Tube laser cutting machines, with their precise control and clean cuts, allow manufacturers to create complex designs while achieving outstanding results.

Tube laser cutting machines offer immense potential for effectively cutting a wide range of materials. If you want to determine which laser tube cutting machine is suitable for your industry or materials, you can refer to this article or contact us for suggestions.