Standard Equipment

- CNC DELEM DA53T with 2D colour graphics

- ACCURL® BGA-2 for X=500mm X,R-Axis

- Tool kit: 4 V die (V=16-22-35-50) series of 835mm punches

- ACCURL Pro Manual wave crowning system

- GIVI optical scales

- Lazer Safe dual beam photocells

- Hoerbiger (HAWEI) hydraulic system

- High efficiency motor – class IE3

- Electrical cabinet with Schneider, Siemens components

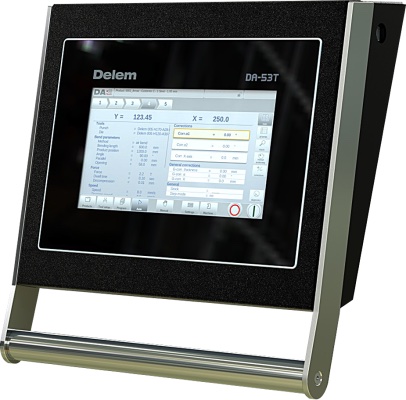

DELEM DA53T Touch CNC System

- 10.1″ high resolution colour TFT

- “Hot-key” touch navigation

- Up to 4 Axis (Y1,Y2 + 2 aux. Axis)

- Tool / material / product library

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- CNC Crowning control

- USB memory stick interfacing

- Profile-53TL offline software

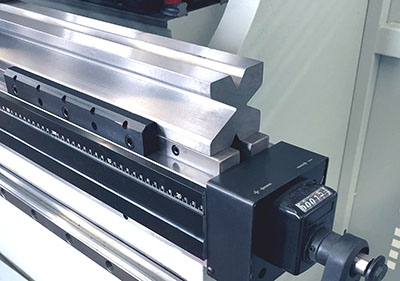

ACCURL BGA-2 Press brake 2-Axis CNC BackGauge with X, R-Axis

ACCURL BGA-2 Press brake 2-Axis CNC BackGauge with X, R-Axis

- Ball screws and linear guide on X, R-axis

- Axis X speed 500 mm/s.

- Manual Z1, Z2-axis with HIWIN linear guide

- Mechanical accuracy ± 0.03 mm.

- Fingers with double stop and micrometric adjustment

ACCURL PPO® Crowning Options

Option 1: CNC Crowning System

- High Precision & Adaptive CNC Crowning System

- By avoiding machine deflection, the ACCURL Crowning™ System creates precise parts, consistently parallel with every run.

Option 2: Manual Crowning

- Very precise bending angles

- Europe type dies with 60 mm and 90 mm

- Base can be clamped as well as single dies with 13 mm tang

- Manual crowning with a handle

- Precise positioning and alignment of the crowning table

- Easy and fast usage

Quick change manual Upper Tool Clamping

ACCURL CNC press brake use all Raw material is provided by qualified suppliers and chemical composition corresponds to international standards. Therefore, raw material yield and tensile strength are guaranteed, are standardized with a 8.4 x 3.5 mm safety groove, which keeps the tool from falling out.

Advantage:

- Safe and fast tool change

- Can be used without modifying Europe type punches

- Front clamp – vertical tool change

- Rear clamp – horizontal tool change

DSP Safety lights