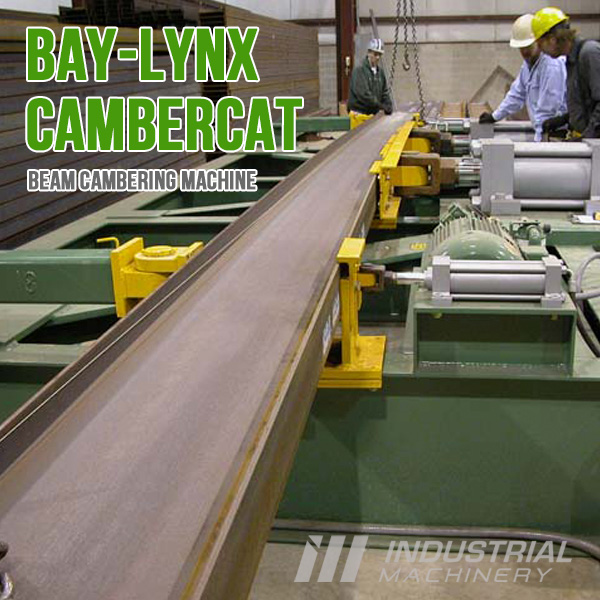

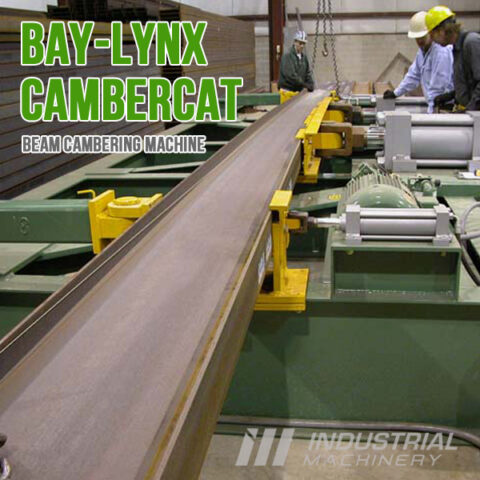

Overview Beam Camber Machine

Our Cambercat Beam Cambering Units are specially designed to induce permanent camber into wide flange, channel and tubular beams. Our machines are designed for ease and speed of operation and are totally self contained so that they may be moved and stored when not in use. All mechanical and hydraulic components are standard items, and parts and service are readily available nationwide.

Kits for Camber Units

All camber machines are available in hydraulic and design kits. With these orders, we supply all components including measuring device, power unit, hydraulic valves, cylinders, hoses and fittings, and a complete set of fabrication and detail drawings.

Optional Features

CMS01 Measuring with Display

Bay-Lynx are the only manufacturer that has the digital readout option, it is a definite must for anyone in the structural steel business for repeatability and accuracy. see attached PDF. This saves time running string lines etc. our system gives you a live read during the camber process our competitors do not

100 AMP Fusible Disconnect (415V / 50HZ /3 PHASE)

Push Button Start/Stop, Motor starter 440 volts. C/W electronic overload.

Include the step down transformer for the digital readout

36” stroke

The benefit to the 36” stroke machine is time savings. It makes it so you do not need to change out the spacer tubes when your beam size changes

Lift and kneeling

Powered rollers with lift, so beam can just go through the line without being lifted off by crane.

Hydraulic Flange Hold Downs

Again all about time saving. If you don’t get them you might need to manually clamp as the beam could possibly shift up during cambering.