Features

- High RPM, high torque spindle

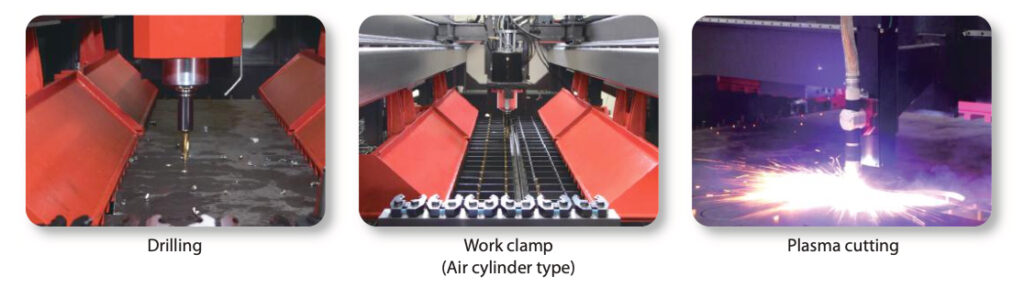

- Fast drilling with tungsten carbide drill

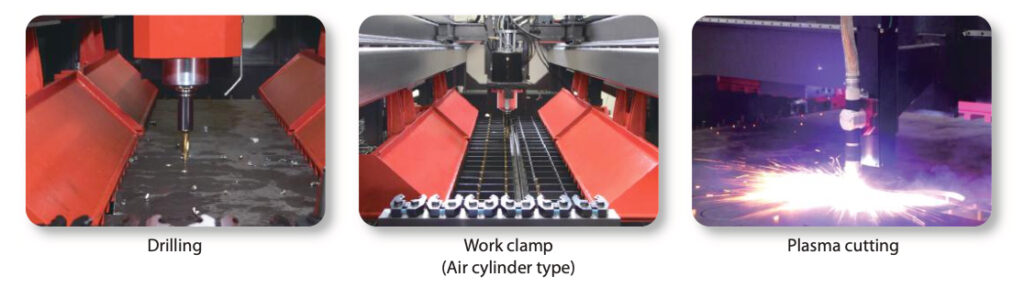

- Fast cutting, no preheating necessary

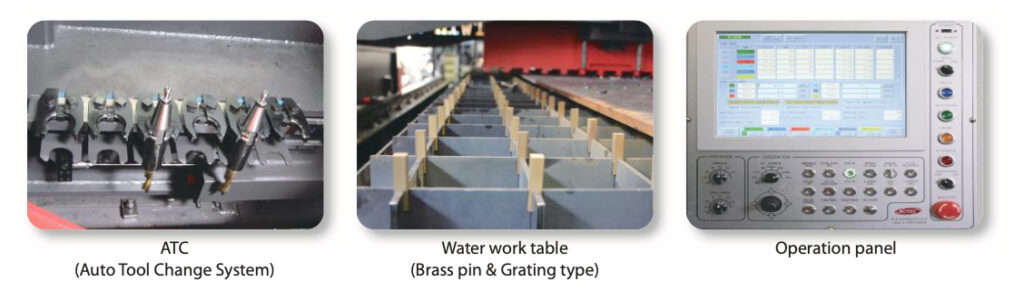

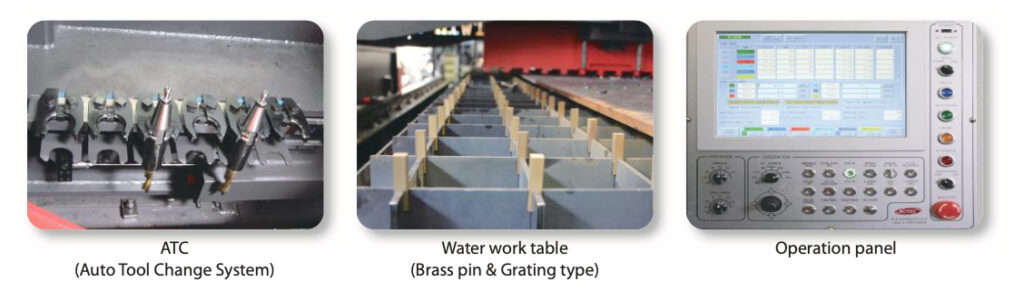

- ATC (Auto Tool Change)

- Multi-production in small space

- Auto nesting program

https://youtu.be/SeV8wYAMILg?si=LE4gENd1m4nYXAC4

Kotec multi-function plate drilling and plasma cutting machine. Complete with the dual gantry design for the fastest and precise drilling, milling and tapping sequences. Cutting is performed by the latest Hypehterm XPR-300 plasma cutting system.

https://youtu.be/SeV8wYAMILg?si=LE4gENd1m4nYXAC4

| Travelling | Dual Gantry type |

| Effective cutting width | 2500 / 3000 mm |

| Effective cutting length | 6000 / 9000 / 12000 mm |

| Drilling Capacity | Ø14 ~ Ø50mm |

| Max. Plate Thickness | 50mm |

| Type of Drill | Oil Hole, Tungsten Carbide Drill, Straight shank |

| Spindle Drill Holder | BT-50 |

| Spindle Motor | Built-in Spindle 18Kw, 8P |

| Spindle RPM | 1800 RPM (Inverter controlled) |

| ATC (automatic tool changer) | 6 tools changer included |

| Oil mist Coolant system | |

| Drill Feeding | LM / Ball screw type, Servo Motor |

| Travelling | Gantry Move by Servo motor |

| Travelling Speed | Max 30m/min. |

| Vertical clamping while drilling | Air cylinder type 4 sets |

| Worktable type | Dry bed |

| Plasma | Hypertherm XPR-300 |

| Fume collector Optional | |

| Air compressor excluded | |

| Controller | Sentrol CNC controller, or equivalent. |