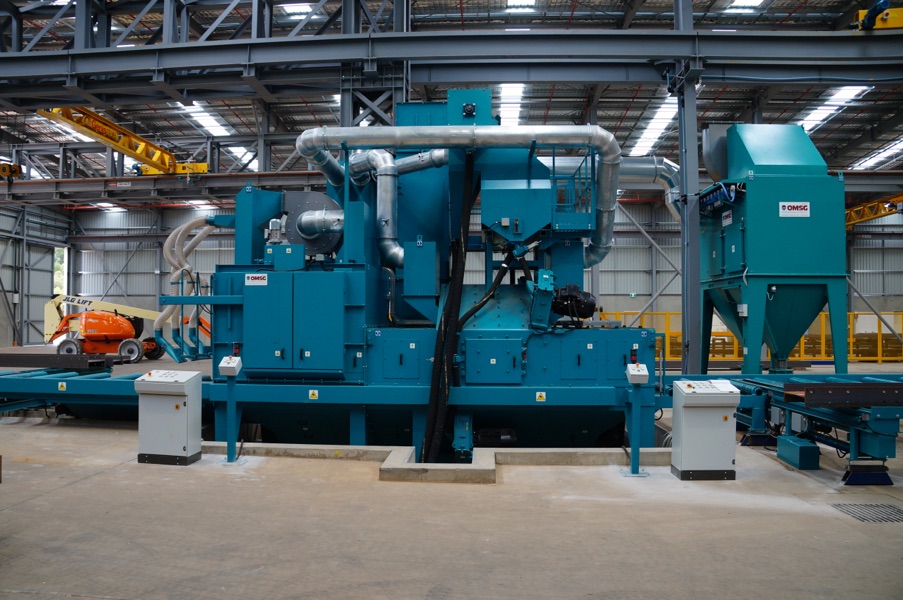

OMSG LAUCO: The Pinnacle of Shot Blast Machines with Roller Conveyors

The LAUCO Shot Blasting Machine redefines the cleaning process with a continuous tunnel chamber fed by a horizontal infeed and exit roller conveyor. Its versatile design accommodates various work sizes, ensuring a single-pass cleaning that meets ISO 8501-1 and SIS SS 055900 standards.

After passing through the blast chamber on driven roller conveyors, the treated components emerge from the machine, free from abrasive residue, thanks to integrated brushing and blowing systems. OMSG offers a range of LAUCO machines to cater to diverse needs and manufacturing requirements:

- Steel Plate and Section Blasting: Ideal for steel plates and sections.

- Pipe Cleaning: Ensures internal and external cleanliness of tubes and pipes.

- Structural Steel Work: Tailored for fabrications and structural steel.

- Integrated Painting: Works seamlessly with automatic painting systems for plates and sections.

- Billet Descaling: Perfect for billet surface preparation.

- Aluminum Extrusions: Designed for aluminum extruded profiles.

LAUCO machines for mild steel plates and profiles offer conveyor widths from 500mm up to 4500mm. Multiple blast wheels with varying motor kW powers are available to meet specific production capacity needs. The external roller conveyor’s length can be customized to customer requirements, with variable speed control through an inverter.

For external pipe cleaning, LAUCO machines share the technical characteristics of steel plate and profile shot blasting, with specialized profiles on external roller conveyors.

When it comes to composite structural steel works, LAUCO machines feature an entrance section of up to 2000mm and multiple blast wheels angled for maximum coverage.

Simultaneous blasting of internal and external pipes is made possible with LAUCO machines equipped with a special roller conveyor with shaped profiles. The key advantage is the ability to blast both externally (through blast wheels) and internally (with a compressed air lance) in a single automated process.

LAUCO machines designed for blasting and painting of steel plates and commercial profiles boast high productivity. The typical layout includes loading cross transfer systems, pre-heating ovens, shot blasting machines, painting booths, drying ovens, and unloading cross transfer systems for rapid discharge.

For billet surface preparation, shot blasting machines feature a handling system with grooved roller conveyors, suitable for moving squared or round billets. These machines are equipped with high-powered blast wheels to ensure high production speeds.

Lastly, the LAUCO shot blasting machine for aluminum extruded profiles includes special devices for treating the surface of extruded aluminum profiles, enhancing their quality and appearance.